The Cellulose Group @ IITH

Group Lead:

Dr. Mudrika Khandelwal

Associate professor

Department of Materials Science and Metallurgical Engineering, IIT Hyderabad

mudrika@msme.iith.ac.inPh.D. University of Cambridge, UK (2013)

M.Tech, B.Tech, Indian Institute of Technology, Bombay (2009)

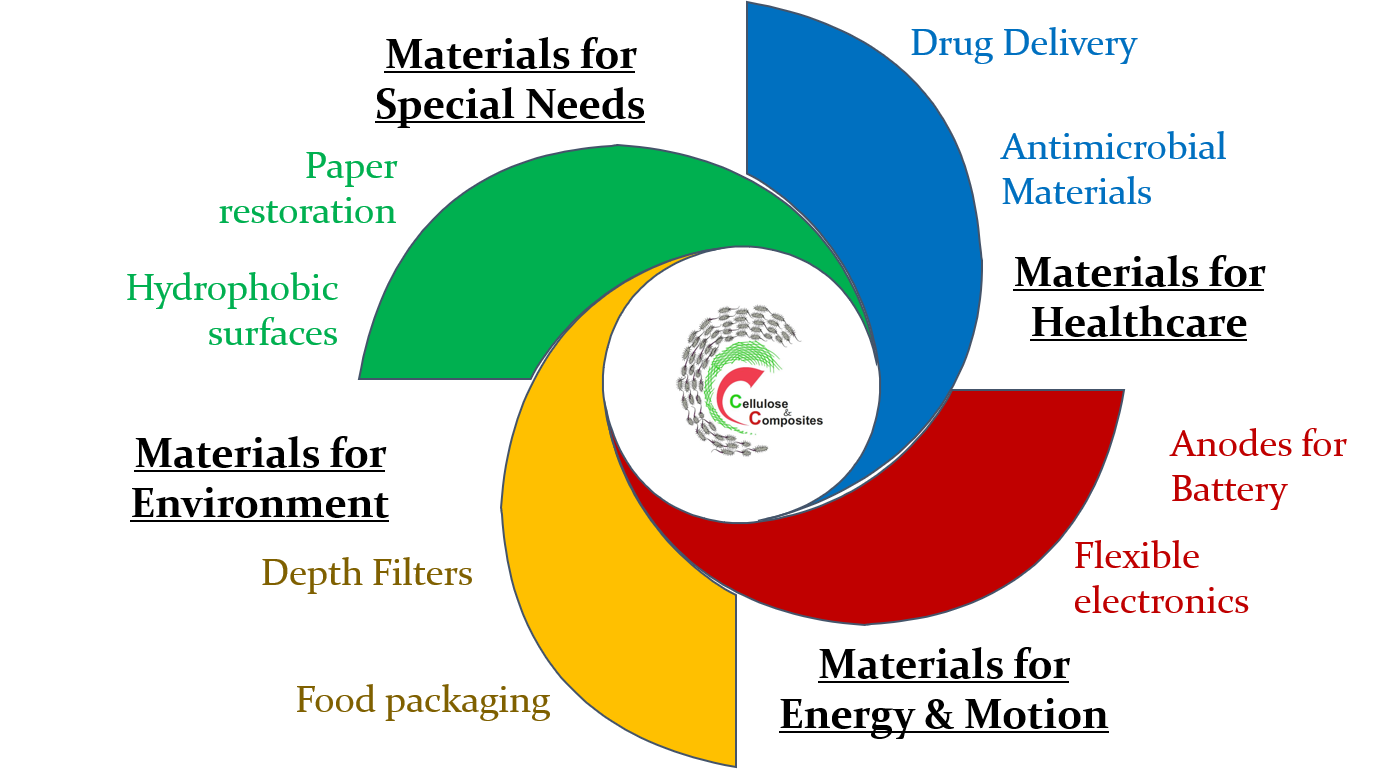

Research Focus:

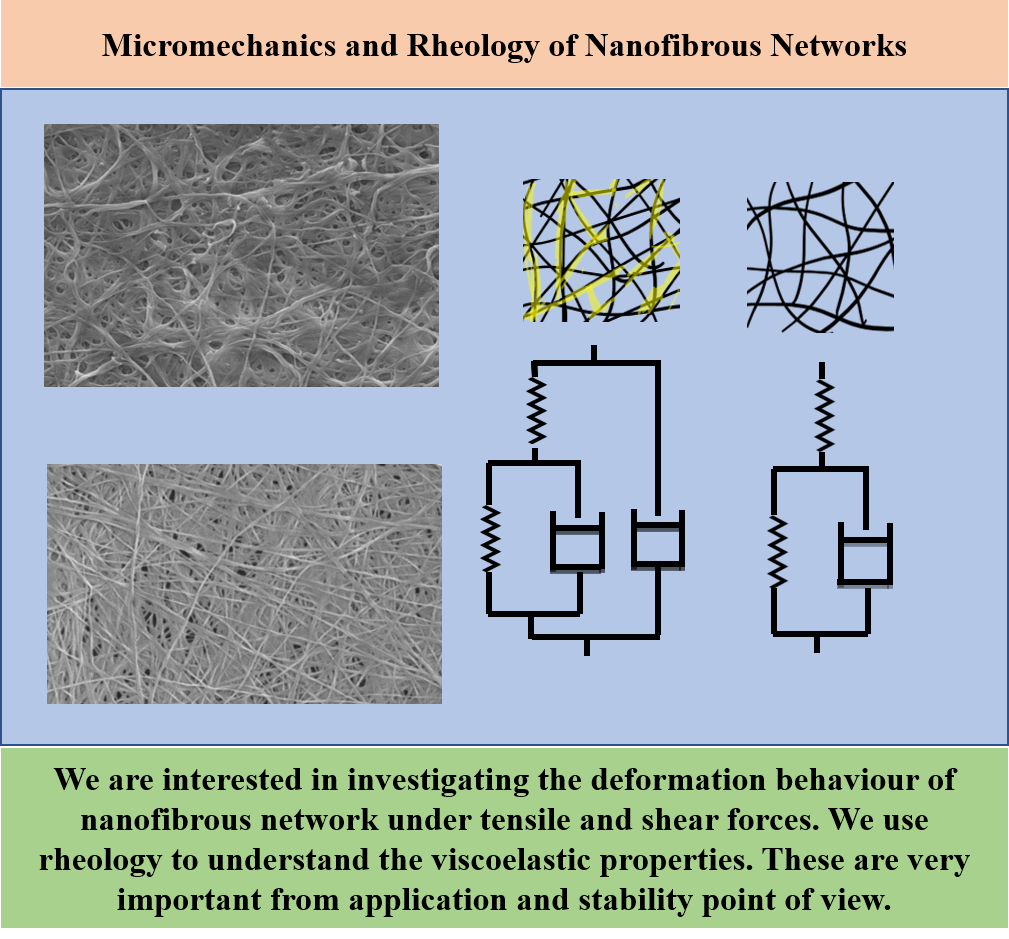

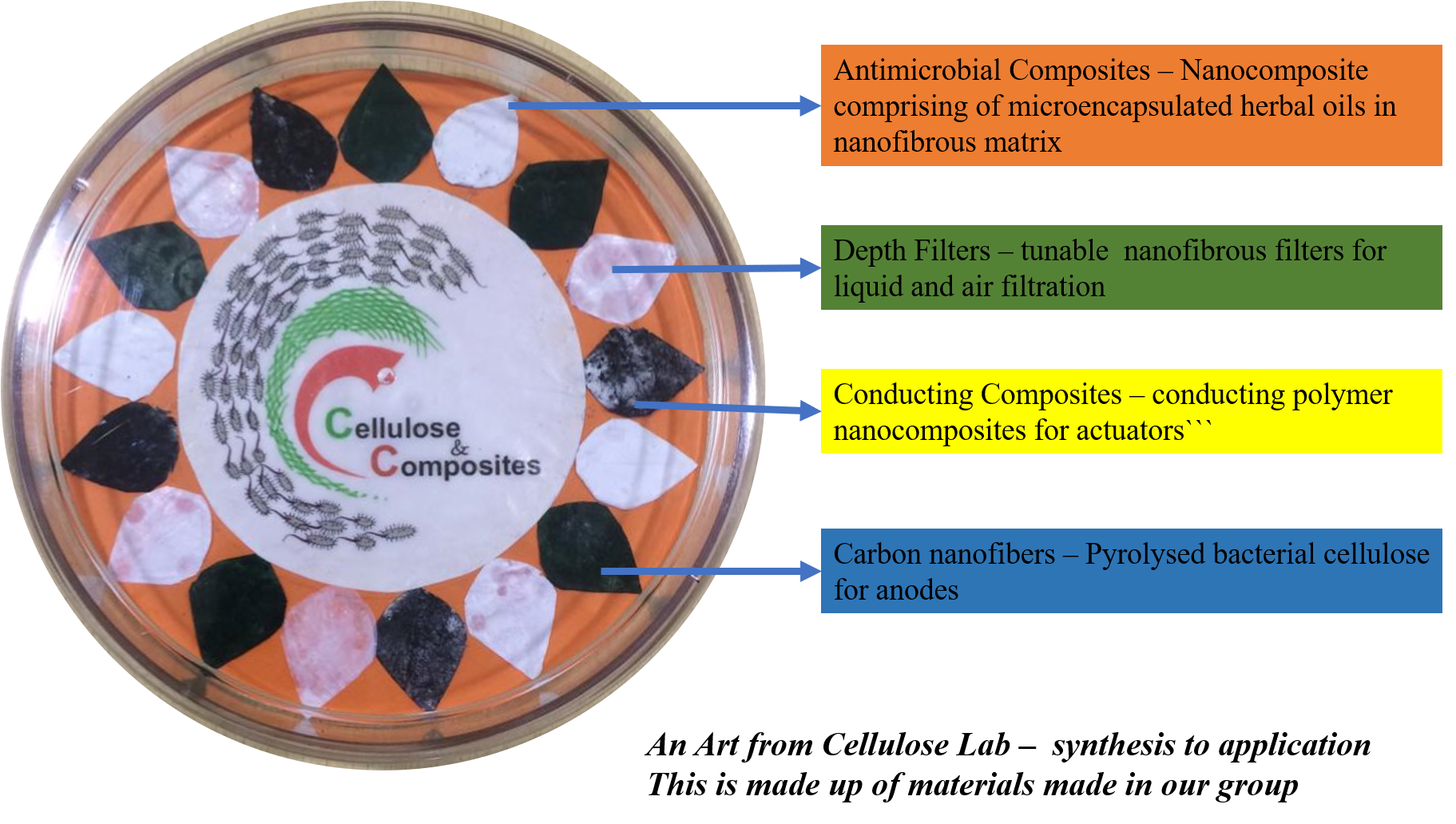

Established in 2013, our group has aimed on finding solutions to some of the technologically and scientifically challenging societal concerns through materials intervention, with a special emphasis on sustainability. The interdisciplinary work carried out by our group is enabled by knowledge of multiple disciplines, materials at different length scales (nano, micro) and inspirations from nature. The primary focus areas (but not limited to) are highlighted below.

Glimpse of Recent Projects

Funded Projects

Ongoing:

SERB women excellence award for 'Modulated dual drug release from nanocellulose for medicated dressing'. 2022-2025.

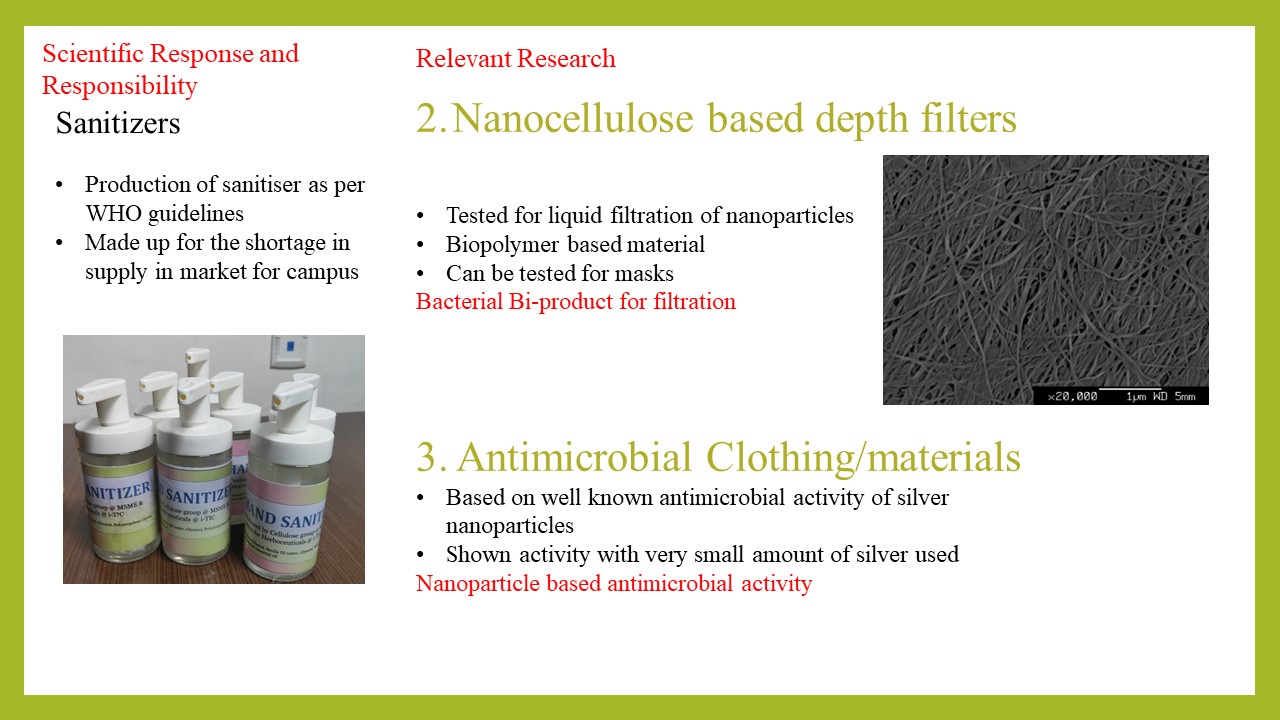

Government of India's National Technical Textiles Mission of the Ministry of Textiles project on 'Biodegradable self-sanitizing bacterial nanocellulose fabric for air and water filtration'. 2022-2025.

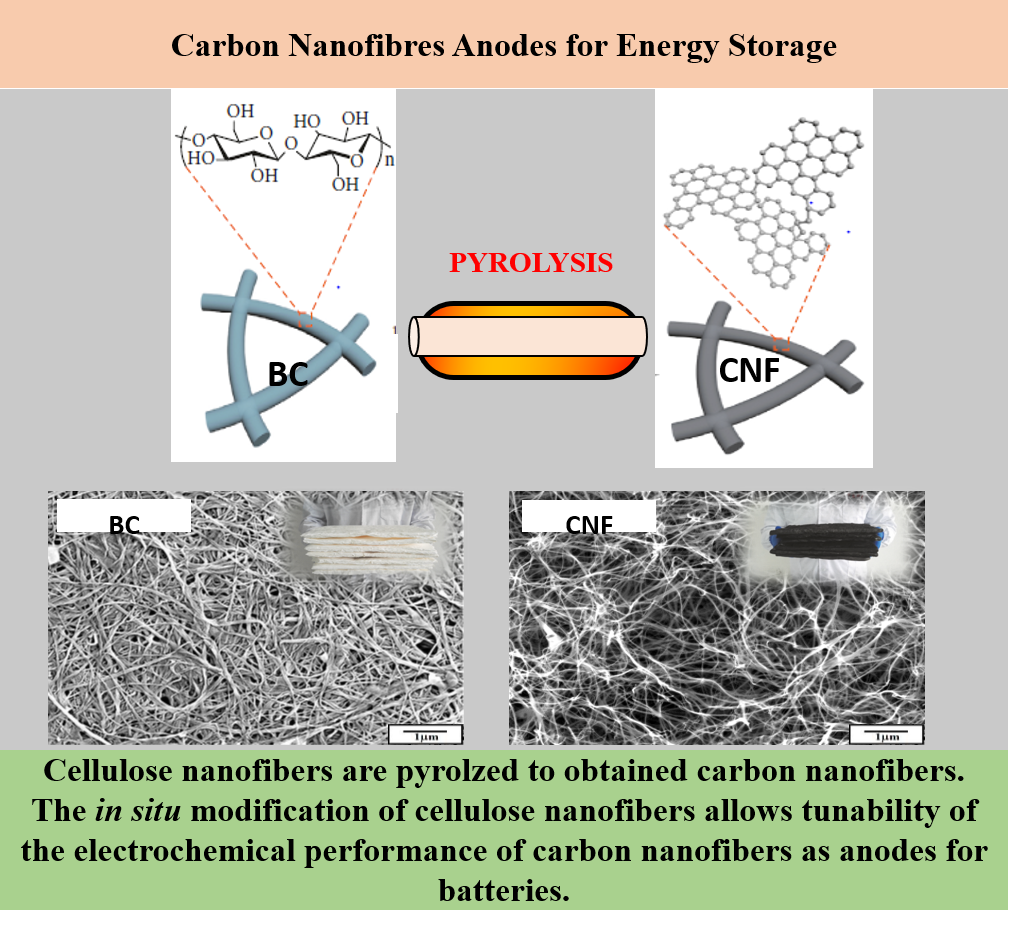

SERB Core research grant on 'Bacterial cellulose derived nanostructured carbon materials with tunable porosity as high performance anode for lithium ion battery' 2019-2022.

Collaborator: Dr. Chandra Shekhar Sharma (Chemical Engineering, IITH)

Completed:

1. DST-UKIERI Project on 'Polymer and Carbon based Three Dimensional Micropatterned Nanofabric with Enhanced Wettability Contrast' 2015-2017

Collaborators -

Dr. Chandra Shekhar Sharma (Chemical Engineering, IITH)

Prof. Stephen Eichhorn (Head, Engineering,Chair in Materials Science within the College of Engineering, Maths and Physical Sciences, University of Exeter)

2. SERB Fast Track for Young Scientists/Start-Up Research Grant (Young Scientists) titled 'Novel low cost antifouling materials for healthcare and food packaging industry.' 2015-2018

Sponsored and Consultancy Projects:

- E-SPIN NANOTECH Pvt. Ltd. - air and water filtration.

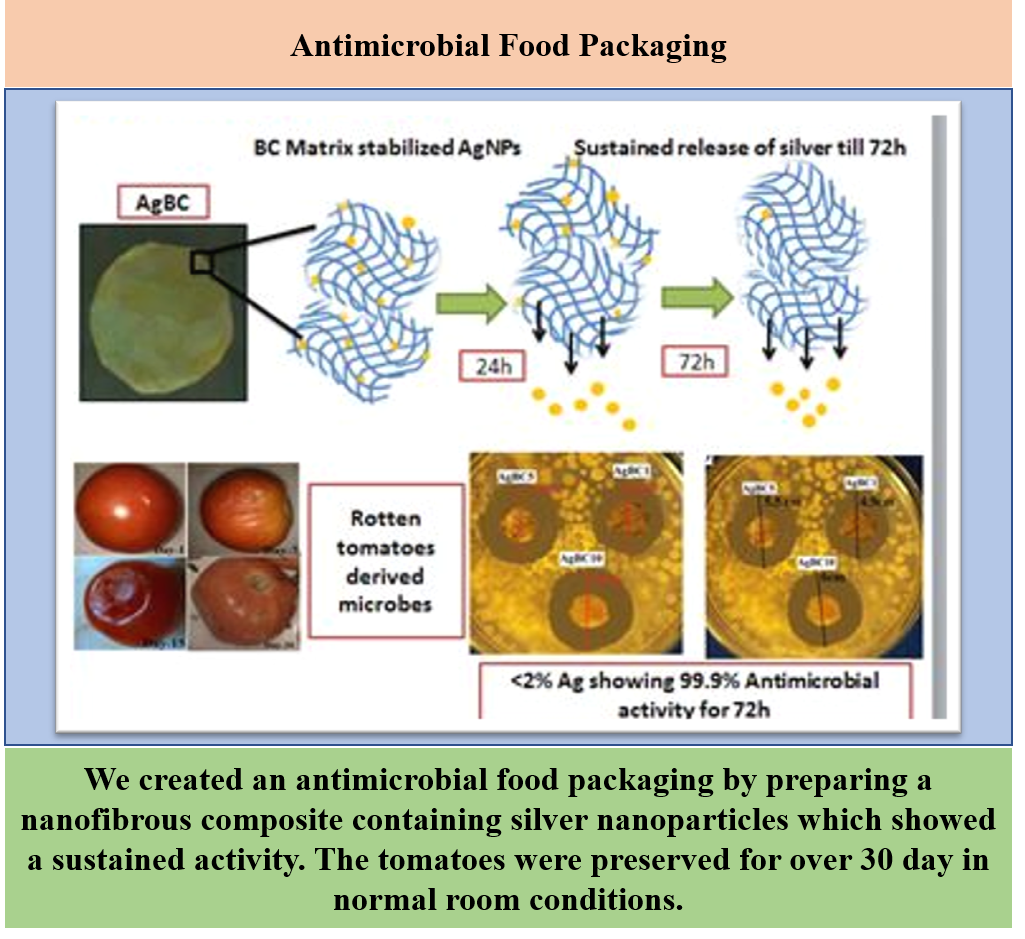

- LDS Pvt. Ltd. - antimicrobial food packaging

- Malai Biomaterials Pvt. Ltd. - artificial leather

- Eaton Pvt. Ltd. - depth filters

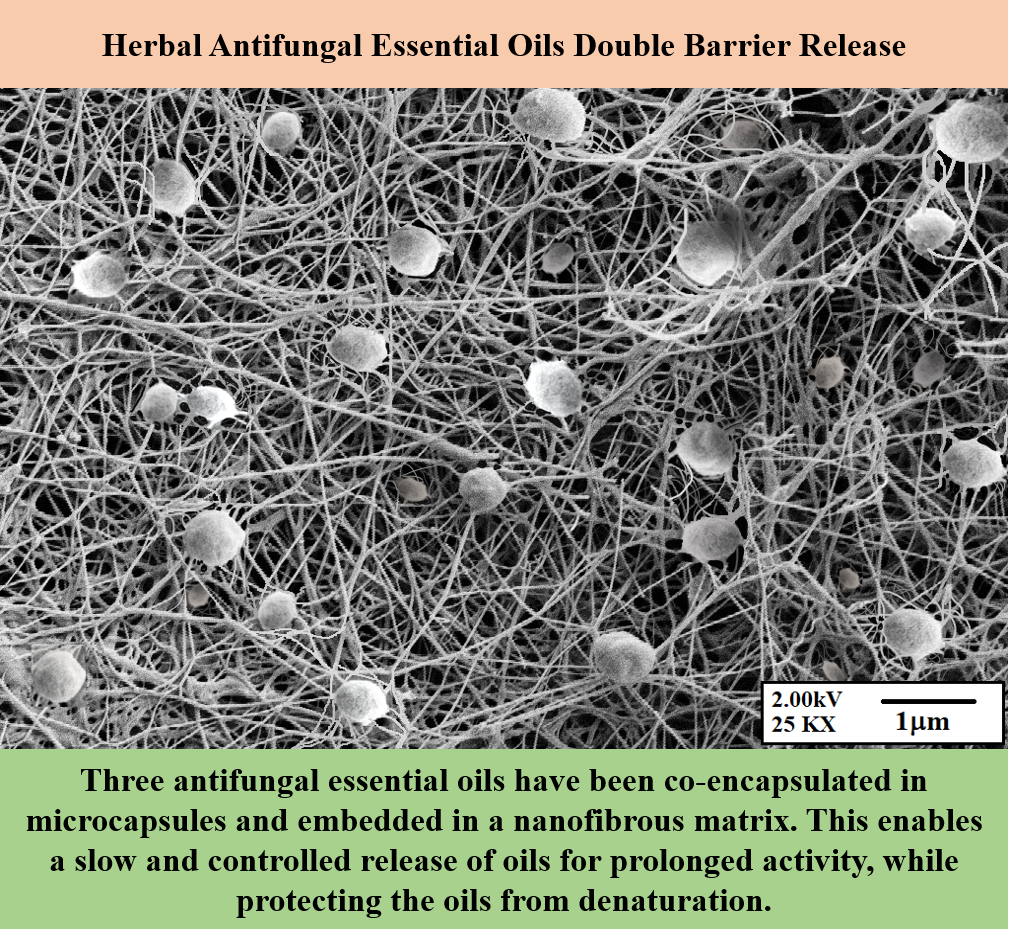

CSR grant by AT&T incorporation for 'Herbal antimicrobial pantyliners for mitigation of vaginal candidiasis'

Publication

Patents

- Provisional patent filed: 'BACTERIAL CELLULOSE BASED MICROFLUIDIC POC DEVICE FOR AST',Application Ref Number-202241030646, Filing Date-27/05/2022 -Indian Patent Office

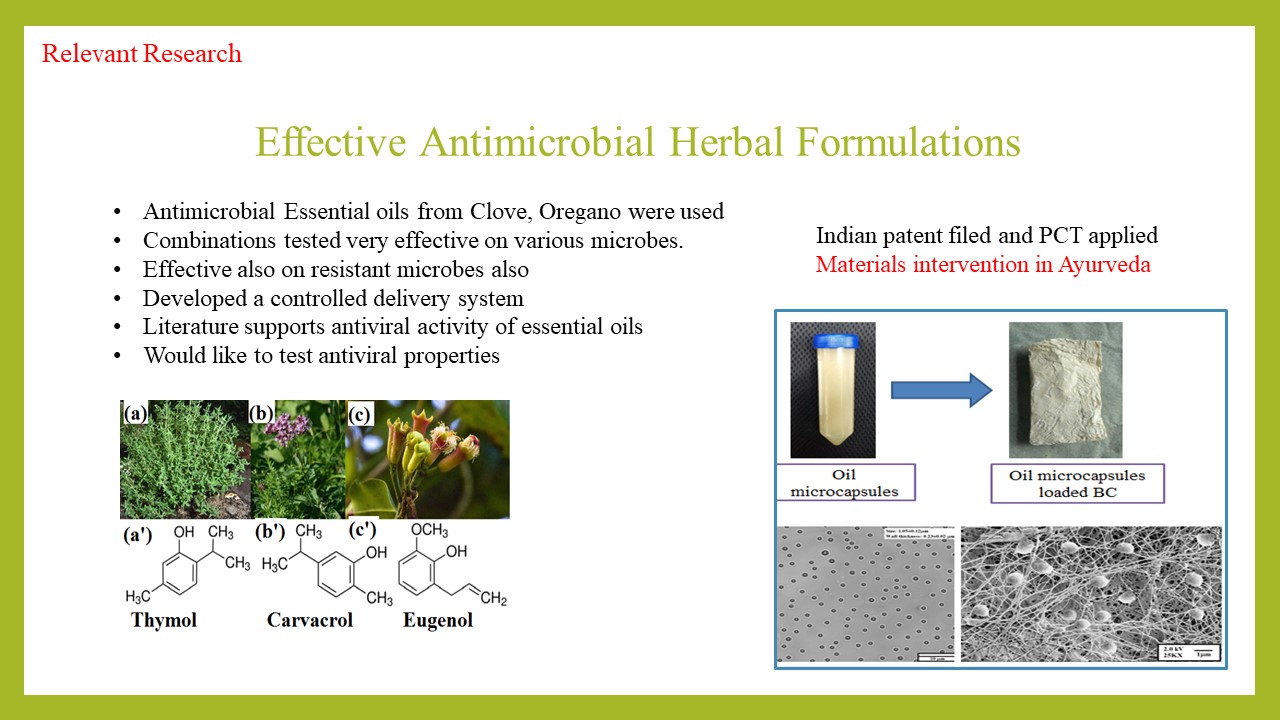

- Pharmaceutical Compositions and Delivery Systems for Prevention and Treatment of Candidiasis, Mudrika Khandelwal, Shivakalyani Adepu, Indian Patent 201841034939, Date of filing: Sept 17 2018,PCT application: PCT/IB2019/057802

- Provisional patent filed: 'Carbon fiber based ethylene adsorber for food packaging application, Application Ref Number-202241063104, Filing Date-04/11/2022 -Indian Patent Office.

Publication

- Vikram Kishore Bharti, Anil Daliprasad Pathak, Chandra Shekhar Sharma, Mudrika Khandelwal. Ultra-high-rate lithium-sulfur batteries with high sulfur loading enabled by Mn2O3-carbonized bacterial cellulose composite as a cathode host.

Electrochimica Acta. Volume 422, 2022: 140531. - Bhagavathi Chalil Najathulla, Atul Suresh Deshpande, Mudrika Khandelwal. PEDOT:PSS/Bacterial Cellulose-based soft actuator under triangle and square wave: Deflection, response and fidelity,

Synthetic Metals. Volume 286, 2022: 117053. - Bhagavathi Chalil Najathulla, Atul Suresh Deshpande & Mudrika Khandelwal. Smartphone camera-based micron-scale displacement measurement: development and application in soft actuators.

Instrumentation Science & Technology. 2022: 1-10. -

S. J. Eichhorn, A. Etale, J. Wang, L. A. Berglund, Y. Li, Y. Cai, C. Chen, E. D. Cranston, M. A. Johns, Z. Fang, G. Li, L. Hu, M. Khandelwal, K.-Y. Lee, K. Oksman, S. Pinitsoontorn, F. Quero, A. Sebastian, M. M. Titirici, Z. Xu, S. Vignolini & B. Frka-Petesic. Current international research into cellulose as a functional nanomaterial for advanced applications.

J Mater Sci. 2022; 57, 5697-5767. -

Urbashi Mahanta, Mudrika Khandelwal, Atul Suresh Deshpande. TiO2@SiO2 nanoparticles for methylene blue removal and photocatalytic degradation under natural sunlight and low-power UV light.

Applied Surface Science. Volume 576, Part A, 2022: 151745. -

Mani Pujitha Illa, Shivakalyani Adepu, Mudrika Khandelwal. Industrial-scale fabrication and functionalization of nanocellulose,Micro and Nano Technologies.

Nanocellulose Materials. 2022: 21-42. -

Mani Pujitha Illa, Kalyani Peddapapannagari, Siju Cherikkattil Raghavan, Mudrika Khandelwal & Chandra S. Sharma. In situ tunability of bacteria derived hierarchical nanocellulose: current status and opportunities.

Cellulose. 2021: 28, 10077-10097. -

Vikram Kishore Bharti, Anil Daliprasad Pathak, Mudrika Khandelwal, Chandra Shekhar Sharma. Mn2O3 Incorporated Carbonized Bacterial Cellulose As Sulfur Host for Lithium-Sulfur Batteries.

The Electrochemical Society Meeting Abstracts. MA 2021-02 34. -

Chandra S Sharma, Mudrika Khandelwal. Polystyrene Recycling to Print Transfer.

Resonance. 2021/9: 1305. -

Chandra S Sharma, Mudrika Khandelwal. Nature Inspires.

Resonance. 2021/9: 1279-1285. - Mahanta U, Khandelwal M, Deshpande AS, Antimicrobial surfaces: a review of synthetic approaches, applicability and outlook.

Journal of Materials Science 2021 - S Adepu, M Khandelwal. Drug release behaviour and mechanism from unmodified and in situ modified bacterial cellulose.

Proceedings of the Indian National Science Academy. 2021 - MP Illa, CS Sharma, M Khandelwal*. Catalytic graphitization of bacterial cellulose-derived carbon nanofibers for stable and enhanced anodic performance of lithium-ion batteries.

Materials Today Chemistry. 2021; 20; 100439 - S Adepu, P Kalyani, M Khandelwal*. Bacterial Cellulose-Based Drug Delivery System for Dual Mode Drug Release.

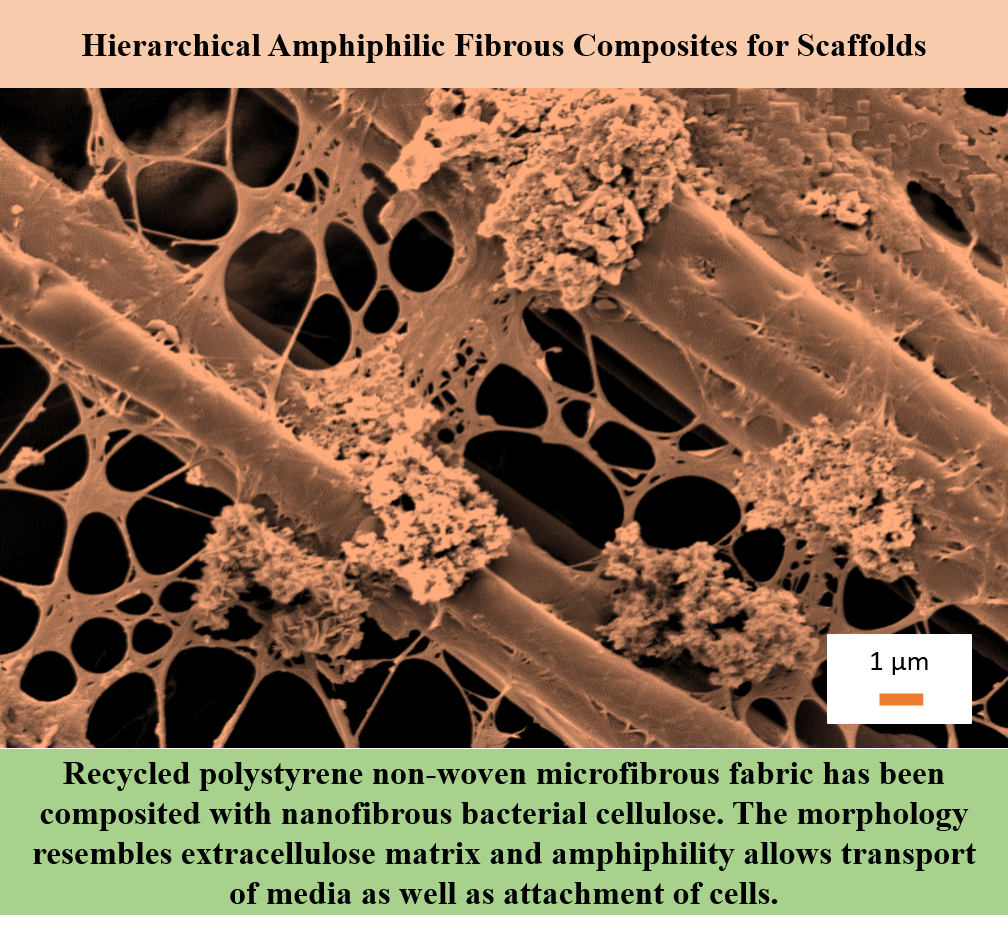

Transactions of the Indian National Academy of Engineering; 2021:1-7 - Raghavan, SC, PV, A, Khandelwal, M*. Hierarchical amphiphilic high‐efficiency oil-water separation membranes from fermentation derived cellulose and recycled polystyrene.

J Appl Polym Sci. 2021; 138:e50123 - Adepu S, Khandelwal M*. Ex-situ modification of bacterial cellulose for immediate and sustained drug release with insights into release mechanism.

Carbohydrate Polymers. 2020:116816 - Mani Pujitha Illa, Anil D Pathak, Chandra S. Sharma, and Mudrika Khandelwal. Bacterial Cellulose-Polyaniline Composite Derived Hierarchical Nitrogen-Doped Porous Carbon Nanofibers as Anode for High-Rate Lithium-Ion Batteries.

ACS Applied Energy Materials 2020 3 (9), 8676-8687 - Anju P, Khandelwal M*, Subahan MP, Kalle AM, Mathaparthi S. In situ synthesized hydro-lipophilic nano and micro fibrous bacterial cellulose: polystyrene composites for tissue scaffolds.

Journal of Materials Science. 2020:1-10. - Adepu S, Khandelwal M*. Bacterial cellulose with microencapsulated antifungal essential oils: a novel double barrier release system.

Materialia. 2020:100585. - Yadav S, Mattaparthi S, Sreenivasulu K, Khandelwal M, Majumdar S, Sharma CS. Recycling of thermoplastic polystyrene waste using citrus peel extract for oil spill remediation.

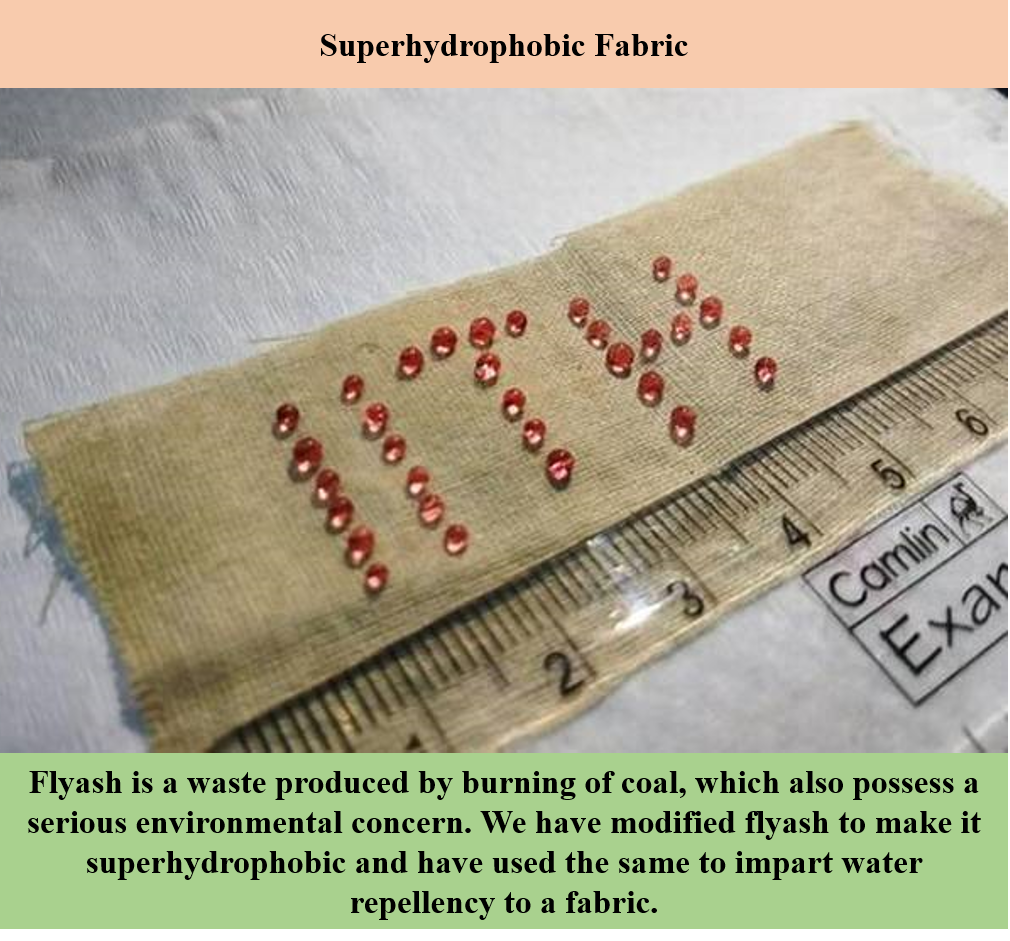

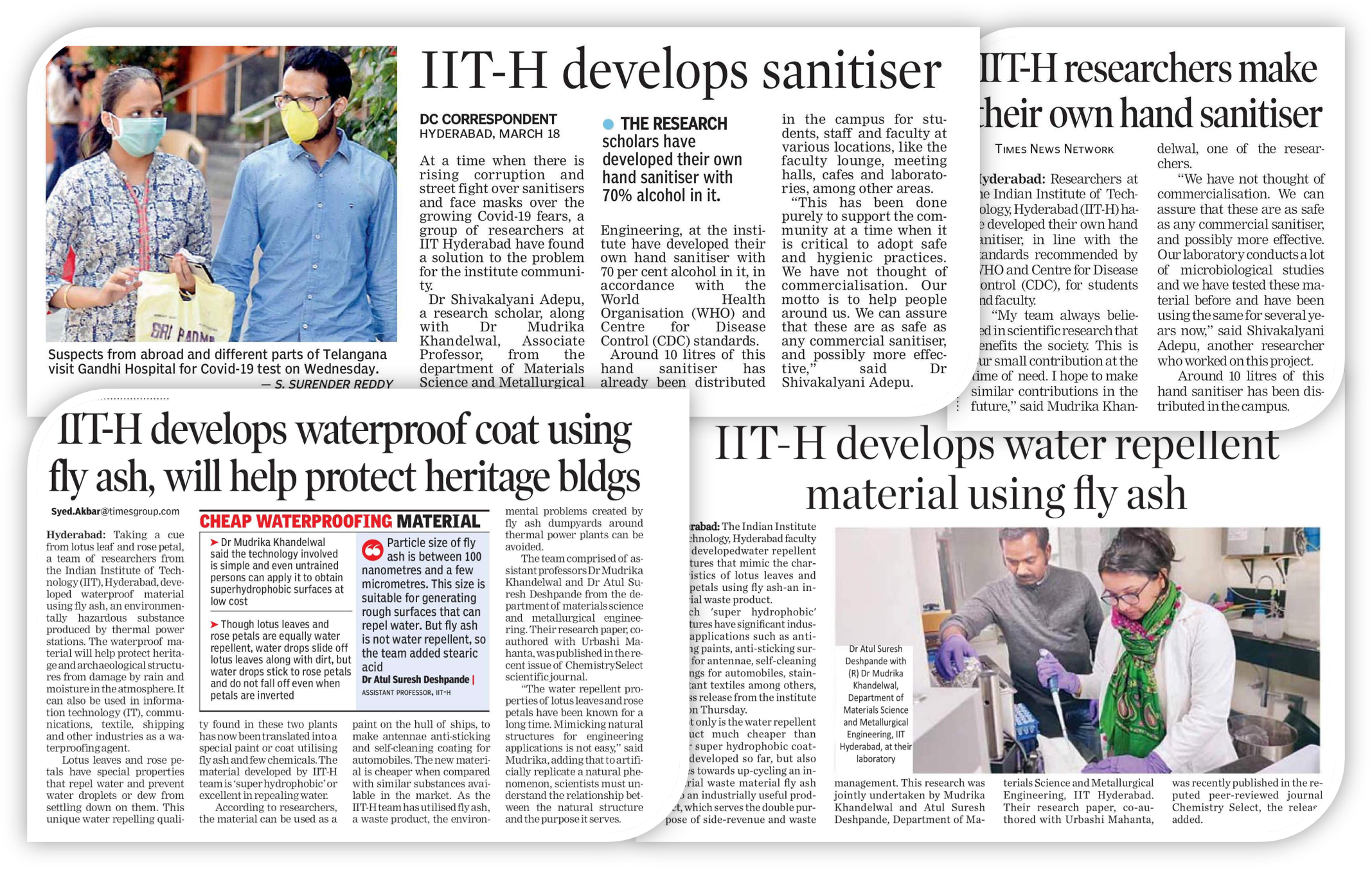

Journal of Applied Polymer Science. 2019;136(33):47886. - Mahanta U, Khandelwal M, Deshpande AS. Wetting Transition from Lotus Leaf to Rose Petal using Modified Fly Ash.

ChemistrySelect. 2019;4(27):7936-42. - Illa MP, Sharma CS, Khandelwal M*. Tuning the physiochemical properties of bacterial cellulose: effect of drying conditions.

Journal of Materials Science. 2019;54(18):12024-35. - Illa MP, Khandelwal M, Sharma CS. Modulated Dehydration for Enhanced Anodic Performance of Bacterial Cellulose derived Carbon Nanofibers.

ChemistrySelect. 2019;4(21):6642-50. - Illa MP, Khandelwal M, Sharma CS. Bacterial cellulose-derived carbon nanofibers as anode for lithium-ion batteries.

Emergent Materials. 2018;1(3-4):105-20. - Gaydhane MK, Mahanta U, Sharma CS, Khandelwal M, Ramakrishna S. Cultured meat: state of the art and future.

Biomanufacturing Reviews. 2018;3(1):1. - Adepu S, Khandelwal M*. Broad-spectrum antimicrobial activity of bacterial cellulose silver nanocomposites with sustained release.

Journal of Materials Science. 2018;53(3):1596-609. - Kakunuri M, Wanasekara ND, Sharma CS, Khandelwal M, Eichhorn SJ. Three‐dimensional electrospun micropatterned cellulose acetate nanofiber surfaces with tunable wettability.

Journal of Applied Polymer Science. 2017;134(15). - Kakunuri M, Khandelwal M, Sharma CS, Eichhorn SJ. Fabrication of bio-inspired hydrophobic self-assembled electrospun nanofiber based hierarchical structures.

Materials Letters. 2017;196:339-42. - Kakunuri M, Araga R, Khandelwal M, Sharma CS. Cellulose Acetate Derived Free-Standing Electrospun Carbon Nanofibrous Mat as Anode Material for Rechargeable Lithium-Ion Battery.

ECS Transactions. 2017;80(10):419. - Adepu S, Gaydhane MK, Kakunuri M, Sharma CS, Khandelwal M*, Eichhorn SJ. Effect of micropatterning induced surface hydrophobicity on drug release from electrospun cellulose acetate nanofibers.

Applied Surface Science. 2017;426:755-62. - Adepu S, Dhiman N, Laha A, Sharma CS, Ramakrishna S, Khandelwal M*. Three-dimensional bioprinting for bone tissue regeneration.

Current Opinion in Biomedical Engineering. 2017;2:22-8. - Maity PC, Khandelwal M*. Synthesis time and temperature effect on polyaniline morphology and conductivity.

American Journal of Materials Synthesis and Processing. 2016;1(4):37. - Khandelwal M*, Windle AH, Hessler N. In situ tunability of bacteria produced cellulose by additives in the culture media.

Journal of materials science. 2016;51(10):4839-44. - Khandelwal M*, Windle AH. Small angle X-ray study of cellulose macromolecules produced by tunicates and bacteria.

International journal of biological macromolecules. 2014;68:215-7. - Khandelwal M*, Windle A. Origin of chiral interactions in cellulose supra-molecular microfibrils.

Carbohydrate polymers. 2014;106:128-31. - Khandelwal, M. and K. Aggarwal, Contextualising engineering education to 21st century-MBA style education for engineering.

Journal of Engineering Education Transformations, 2016 - Ramakrishna, P.S. and M. Khandelwal, Attributes of engineers and engineering education for the 21st century world.

Journal of Engineering Education Transformations, 2014. 27(4): p. 17-28.

Other Papers

- Khandelwal M, Windle AH. Hierarchical Organisation in the Most Abundant Biopolymer-Cellulose. MRS Online Proceedings Library Archive. 2013;1504.

- Khandelwal M, Windle AH. Self-assembly of bacterial and tunicate cellulose nanowhiskers. Polymer. 2013;54(19):5199-206.

- Khandelwal M, Hessler N, Windle AH. Effect of modification in cellulose microstructure on liquid crystallinity. MRS Online Proceedings Library Archive. 2013; 1498:221-6.

- Khandelwal M, Windle AH. Structure and Low Concentration Self Assembly of Food Grade Bacterial Cellulose Nano-Whiskers. MRS Online Proceedings Library Archive. 2012;1420.

- Khandelwal M, Venkatasubramanian A, Prasanna T, Gopalan P. Correlation between microstructure and electrical conductivity in composite electrolytes containing Gd-doped ceria and Gd-doped barium cerate. Journal of the European Ceramic Society. 2011;31(4):559-68.

Recognition

Awards

Mudrika Khandelwal's all the achievements followed by others achivements- Mudrika Khandelwal appointed as Dean of Alumni Relations of Indian Institute of Technology, Hyderabad in April 2022.

- Mudrika Khandelwal received prestigious “Women Excellence Award” 2022 of Science and Engineering Research Board (SERB), Department of Science and Technology, Government of India.

- Mudrika Khandelwal received “Faculty Research Excellence” award from the Indian Institute of Technology Hyderabad for the year 2021, in recognition of her outstanding research contribution (below 40 years age category).

- Mudrika Khandelwal inducted as Young Associate of the Indian National Academy of Engineering in 2020.

- Urbashi Mahanta secured Excellence in Research Awards during Ph.D at IIT Hyderabad in 2022.

- Vikram Kishore Bharti secured First Prize in Chemical Sciences category in the Saransh, a National Level Science Communication Competition organized by INYAS.

- Mudrika Khandelwal received Platinum Jubilee Young Scientist Award National Academy of Sciences India 2021

- Mudrika Khandelwal received Young Engineer Award from Indian National Academy of Engineers 2020

- Shivakalyani Adepu received INYAS Excellence in Nano Innovation Award 2020

- Divya Anand bagged the GYTI (Gandhian Young Technological Innovation) award for conducting composites, in the year 2016.

- Shivakalyani Adepu received BIRAC BIG grant 14th call, 2019

- Shivakalyani secured "Excellence in Research award" during Ph.D at IIT Hyderabad in 2018

- Shivakalyani secured GYTI (Gandhian Young Technological Innovation) award for developing a novel drug delivery coating for cardiac stent, in the year 2016.

Tweets about us

Lab in news

People

PhD

Anurag Kumar

High Performance Fibers

Joint Doctoral Student-Deakin University Australia

Co-supervisor: Dr. Maryam Naebe (Deakin University)

Mohammed Arif Khan

Modulated dual drug release from nanocellulose for mediated dressing

Project Associate

Aszad Alam

Actuated drug delivery systems

IITH-SUT joint doctoral student

Co-supervisor: Dr. Aimin Yu (Associate Professor, SUT)

Peddapappanagari Kalyani

Bacterial cellulose composites and in situ modifications for food packaging and drug delivery

Sponsored by Waycool Pvt. Ltd

Samuel Kaki

Tunable Nanofibrous depth filters: design and application in air and liquid filtration

Interdisciplinary joint student

Co-supervisor: Dr. Seetha N.

Sukesh Kumar

Conducting polymer-based actuators and sensors

IITH-SUT joint doctoral student

Co-supervisor: Dr. Aimin Yu (Associate Professor, SUT)

Najathulla BC

Conducting composites for actuator, drug delivery

Co-supervisor: Dr. Atul S. Deshpande

Vikram Kishore Bharti

Prime Minister Research Fellow

Co-supervisor: Dr. Chandra Shekhar Sharma

Bacterial Cellulose derived carbon for energy storage

M.Tech

Partha Pratim Das

Biodegradable food packaging for fresh produce: Shelf life extension

Ashish Priyam Goswami

Bacterial cellulose based functionalized carbon nano fibres as electrode for metal sulphur batteries

Co-supervisor: Dr. Chandra S. Sharma

Saritha

Microfluidics aided patterned nanofibrous materials based on bacterial cellulose

Co-supervisor: Dr. Suhanya Duraiswamy

Alumni

Dr. Siju C. R.

Contribution to group: Post-Doctoral

Dr. Shivakalyani Adepu

Contribution to group: Post-Doctoral (Drug delivery, antimicrobial materials)

Current Affiliation: Project Investigator, BIRAC Biotechnological Ignition Grant

Incubated i-TIC, IIT Hyderabad

Dr. Urbashi Mahanta

Contribution to group: Ph.D (Wettability tuning, Hydrophobic coatings, antimicrobial surfaces)

Dr. Illa Mani Pujitha

Contribution to group: Ph.D (Bacterial cellulose based carbon anode for lithium ion batteries)

Current Affiliation: Institute Post-doctoral Fellow, IIT Bombay

Pintu Maity

Contribution to group: M.Tech (conducting polymer based monolithic actuators)

Current Affiliation: Doctoral candidate, IIT Kharagpur

Dr. Divya Anand

Contribution to group: M.Tech (conducting composites)

Current Affiliation: Technological Environment Maintenance Specialist,

Nippon Paint Holdings Co Ltd, Japan

Dr. Manohar Kakunuri

Contribution to group: Post-Doc Fellow (electrospun materials for energy, health & environment)

Current Affiliation: Assistant Professor, Dept of Chemical Engineering

National Institute of Technology, Warangal

Mr. Palash Chandra Maity

Contribution to group: M.Tech (conducting composites)

Current Affiliation: Pursuing PhD at IIT Roorkee

Mr. Debabrata Palai

Contribution to group: M.Tech (depth filters)

Current Affiliation: Pursuing PhD at Tokyo Institute of Technology

Ms. Anju P. V.

Contribution to group: M.Tech (in situ composites for scaffolds, packaging, filtration)

Current Affiliation: Offered PhD at Hokkaido University

Mukul Choudhary

Contribution to group: M.Tech (Microfluidic devices based on bacterial cellulose)

Aditya Burla

Contribution to group: M.Tech (Antifouling materials based on high entropy alloys)

Apurva Anjan

Contribution to group: M.Tech (Bacterial cellulose-based batteries)

Collaborators

Dr. Atul S. Deshpande

Associate Professor, Dept. of Materials science and Metallurgical Engineering

IIT Hyderabad

Dr. Chandra Shekhar Sharma

Associate Professor, Dept. of Chemical Engineering

IIT Hyderabad

Dr. Arunasree M. Kalle

Associate Professor, School of Life Sciences

University of Hyderabad

Dr. Mayur Vaidya

Assistant Professor, Dept. of Materials Science and Metallurgical Engineering

IIT Hyderabad

Dr. Aimin Yu

Associate professor, Dept. of Chemistry and Biotechnology

Swinburne University of Technology, Australia

Dr. Veda Krishnan

Scientist, Biochemistry Department

Indian Agricultural Research Institute, New Delhi

Prof. Stephen Eichhorn

Bristol, Composites Institute

University of Bristol, UK

Dr. Bharat B. Panigrahi

Associate Professor, Dept. of Materials Science And Metallurgical Engineering

IIT Hyderabad

Prof. Seeram Ramakrishna

Dept. of Mechanical Engineering

National University of Singapore

Prof. Peter Kingshott

Professor of Surface Engineering

Swinburne University, Australia

Prof. Stevan Langford

Professor of Chemistry

Associate Dean Research

School of Science, Computing and Engineering Technologies

Swinburne University of Technology

Dr. Seetha N

Associate Professor

Department of Civil Engineering

IIT Hyderabad

Dr. Suhanya Duraiswamy

Assistant Professor

Department of Chemical Engineering

IIT Hyderabad

Industry Collaborators

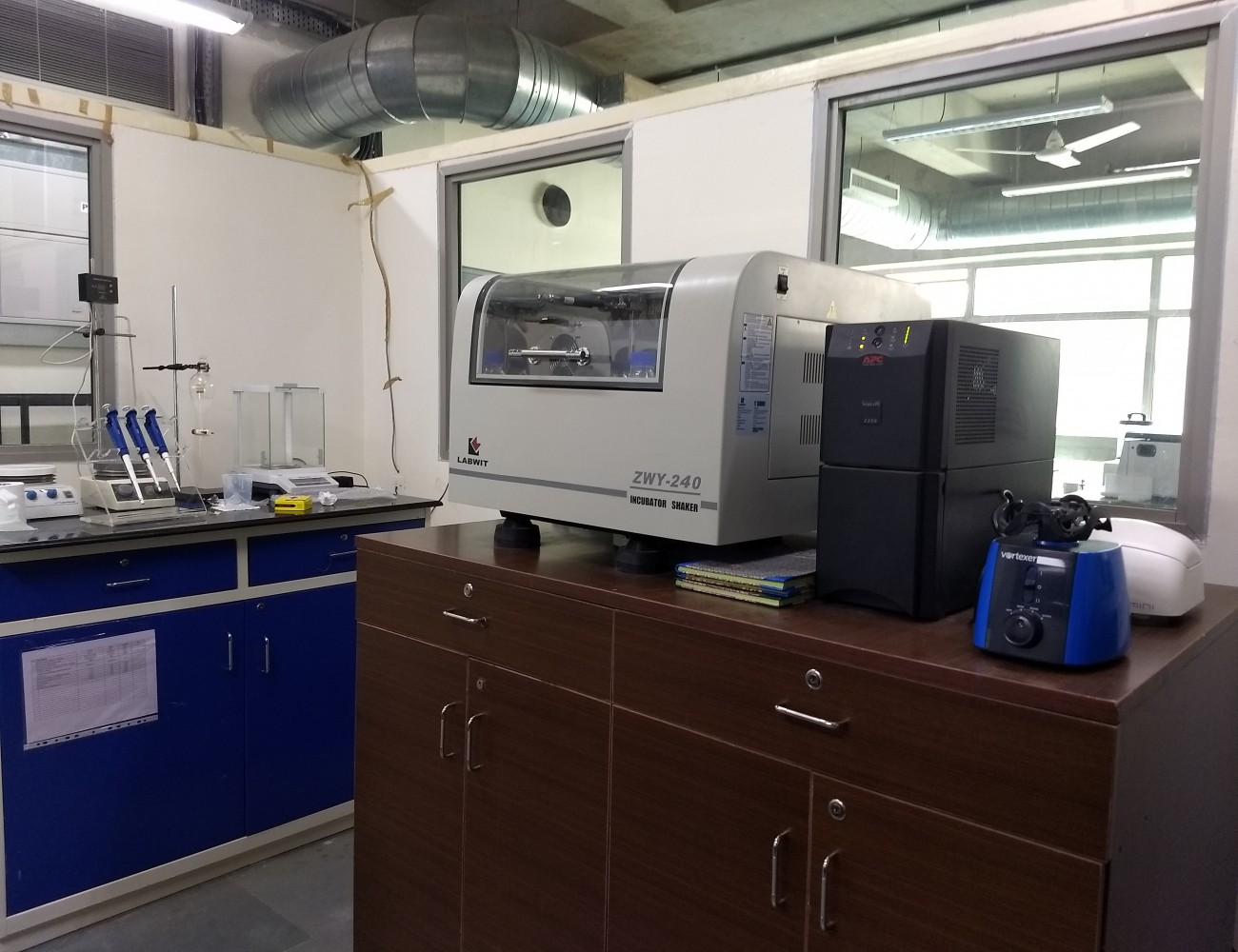

Facilities

Our lab is equippied with the following

- Autoclave

- Battery testing system

- Biosafety Cabinet

- Centrifuge

- Drug release Franz diffusion setup

- Freeze Dryer

- Hot air oven

- Hot Plates

- Incubator maintained at 25 ℃ and 37 ℃

- pH meter

- Stability Chamber

- Ultrasonicator

- UV-vis spectrophotometer

- Vacuum oven

- Viscosity Meter

- Vortexer

- Water Bath

- Weighing balance

Teaching

Course

Credits

Suitable for

Science and Engineering of Materials

1 credit

UG

Polymers

1 credit

3 credit

UG

Structural and functional polymers

1 credit

3 credit

UG, PG

Soft matter science

1 credit

3 credit

UG, PG

Nature inspired materials engineering

1 credit

2 credit

UG, PG

Hierarchical and Supramolecular materials

1 credit

UG, PG

Antifouling and antimicrobial materials (TBI)

1 credit

UG, PG

Life cycle assessment (TBI)

1 credit

UG, PG

Opportunities

Our lab is equippied with the following

- Autoclave

- Battery testing system

- Biosafety Cabinet

- Centrifuge

- Drug release Franz diffusion setup

- Freeze Dryer

- Hot air oven

- Hot Plates

- Incubator maintained at 25 ℃ and 37 ℃

- pH meter

- Stability Chamber

- Ultrasonicator

- UV-vis spectrophotometer

- Vacuum oven

- Viscosity Meter

- Vortexer

- Water Bath

- Weighing balance

| Course | Credits | Suitable for |

|---|---|---|

| Science and Engineering of Materials | 1 credit | UG |

| Polymers | 1 credit 3 credit |

UG |

| Structural and functional polymers | 1 credit 3 credit |

UG, PG |

| Soft matter science | 1 credit 3 credit |

UG, PG |

| Nature inspired materials engineering | 1 credit 2 credit |

UG, PG |

| Hierarchical and Supramolecular materials | 1 credit | UG, PG |

| Antifouling and antimicrobial materials (TBI) | 1 credit | UG, PG |

| Life cycle assessment (TBI) | 1 credit | UG, PG |

If you believe ‘materials enable better life’

We invite you to apply with us @ Cellulose Group

We can work together through

- Internships

- e-Internships (especially during this pandemic)

- External bachelor and master projects

- PhD

- Post-Doctoral Fellow

- Project Staff

You may reach us at cellulosegroup@iith.ac.in

COVID